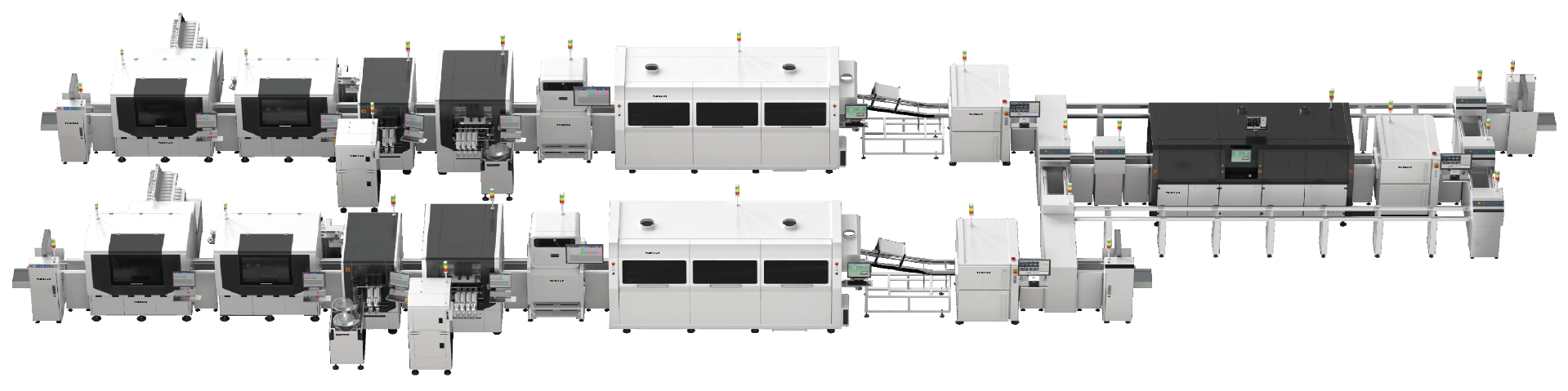

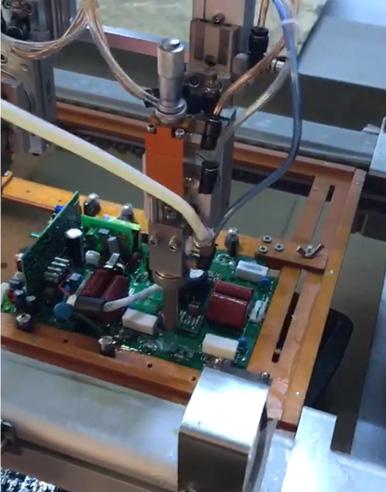

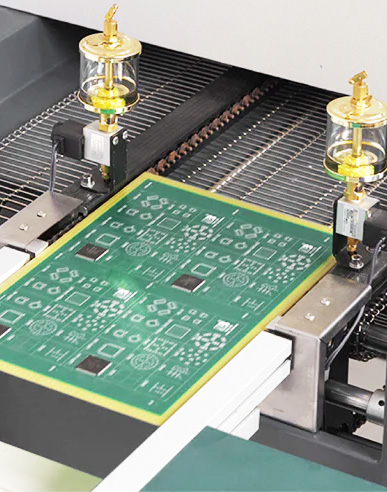

SMT Knowledge Center Practical Knowledge for Stable SMT Production and Smart Equipment DecisionsThe SMT Knowledge Center is designed for engineers, production managers, and buyers who want to understand problems, make correct decisions, and build stable SMT lines.This center connects real production

Apr 13,2026