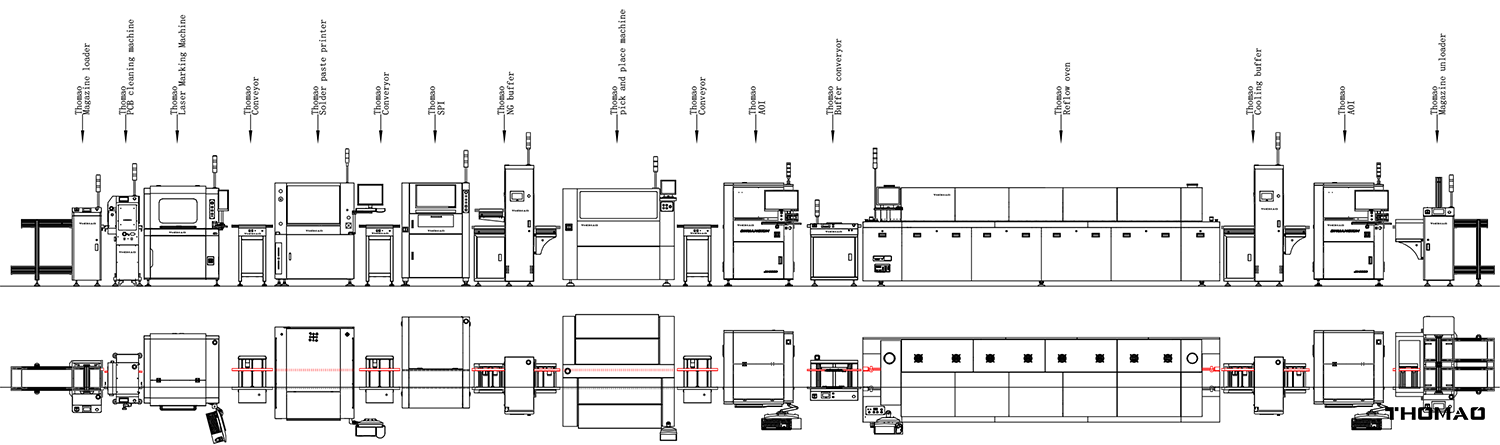

SMT Production Line

Setting up a new SMT production line is a complex systemic project, involving technology, equipment, materials, personnel, and management. Thorough planning is key to a successful launch and future stable and efficient operation.

SMT Production Line

Setting up a new SMT production line generally requires several materials and information, such as product Gerber files, component BOM tables, CAD component coordinate tables, and the factory's planned production capacity.

The following are detailed considerations from four perspectives: preliminary planning, equipment selection, supporting facilities, and personnel and management:

1. Preliminary Planning and Assessment (Important)

This is the most prone to problems and often overlooked.

Product and Process Requirements Analysis:

Product Type: Is it consumer electronics, automotive electronics, medical, or military? This determines the quality standards and requirements.

PCB Characteristics: Board material, size, thickness, maximum/minimum dimensions.

Component Range: Package types (0201, 01005, QFN, BGA, PoP, etc.), special-shaped components, connectors, and heat sinks.

Process Capabilities: Is double-sided placement, through-hole assembly, selective coating, dispensing, online/offline AOI/SPI, or X-ray inspection required?

Mixed Line Production: Is frequent product changeover required? This directly affects the equipment changeover speed requirements.

Product Capacity and Cycle Time Calculation:

Target Output: What are the daily, monthly, and annual production targets?

Theoretical Cycle Time: Calculate the cycle time of the bottleneck equipment based on the product count (number of components) and the equipment's theoretical CPH (components per hour).

Overall efficiency considerations: The overall efficiency of the equipment must be considered, including factors such as line changeover time, planned maintenance, and downtime due to failures. Actual production capacity is typically 65%-85% of theoretical capacity.

Budget and Return on Investment:

Equipment investment: This includes not only the main machine but also auxiliary equipment, spare parts, and installation and commissioning costs.

Operating costs: Electricity, gas, consumables (solder paste, red glue, stencils, nozzles), maintenance costs, and labor costs.

ROI Analysis: Calculate the payback period based on production capacity and product profit.

Future Scalability:

Are there plans for new products or processes (such as Mini LED) in the next two to three years?

Does the production line layout allow for additional equipment or functional modules?

II. Core Equipment Selection and Technical Considerations

This is the core of the production line and requires continuous improvement.

Solder Paste Printer:

Precision and Stability: For fine-pitch components (such as 0.4mm pitch BGAs), printing accuracy and repeatability are crucial.

Automation: Does the machine have automatic stencil wiping, automatic solder paste addition, and integrated 2D/3D SPI? 3D SPI can effectively detect solder paste volume, height, and area.

Substrate Support: Is it a universal magnetic ejector platform or a custom fixture? Ensure the support is flat to prevent PCB deformation.

Placement Machine:

Speed and Precision Balance: A combination of a high-speed machine and a multi-function machine is a common solution. High-speed machines place small components like resistors and capacitors, while multi-function machines place odd-shaped, large-sized, and fine-pitch ICs.

Placement Head and Feeder: Confirm the placement head's capabilities (can it handle both a motorized feeder and a tray?) and assess the required feeder requirements (8mm, 12mm, 24mm, tape, tube, or reel) and quantity.

Vision System: Camera resolution, lighting (multi-color), and recognition algorithms (capability to recognize irregularly shaped and reflective components) are key.

Line Changeover Efficiency: Automatic nozzle changers, trolley-type feeder platforms, and programmatic management can significantly reduce line changeover time.

Reflow Oven:

Number of Temperature Zones: At least 8-10 zones. Complex lead-free processes or large-sized boards may require 12-14 zones.

Heating Method and Heat Transfer: Hot air or infrared? Forced hot air is currently the mainstream. Consider heating uniformity for heat sinks and large-sized components.

Nitrogen Capability: Is it necessary? It is beneficial for no-clean processes, reduces oxidation, and improves soldering quality (especially for QFNs), but it increases operating costs.

Cooling Efficiency: A good cooling system is crucial for solder joint crystallization and reliability.

Energy Consumption: Reflow ovens consume a lot of electricity, so energy-saving design is important.

Inspection Equipment:

SPI: 3D SPI is highly recommended. "Quality is printed." SPI can effectively prevent defects after placement and reflow.

AOI: Placed after reflow, inspect for solder joint defects, missed placement, incorrect parts, reverse polarity, and more. Choose equipment with simple programming, stable inspection algorithms, and low false alarm rates.

X-Ray: Required for products with hidden solder joints, such as BGAs, QFNs, and through-hole reflow. Focus on its resolution and penetration capability.

III. Supporting Facilities and Production Environment

"If you want to do your work well, you must first sharpen your tools."

Workshop Environment:

Cleanliness and Temperature and Humidity: A dust-free workshop (typically Class 10,000 or Class 100,000), with strictly controlled temperature (23 ± 3°C) and humidity (40-60% RH) to prevent component oxidation and solder paste performance changes.

Anti-static: A complete ESD protection system, including anti-static flooring, workbenches, wrist straps, and delivery vehicles.

Lighting: Adequate lighting, especially in the inspection area.

Utilities:

Electricity: Total equipment power, voltage stability (a voltage regulator may be required), and independent grounding.

Compressed Air: Stable, clean, and dry compressed air is required (dew point, oil content, and dust particle content are specified). A precision filter and dryer are required.

Exhaust: Reflow ovens and wave soldering machines require exhaust ducting to remove flux fumes and other substances from the workshop.

Auxiliary Equipment and Material Management:

Board Loader/Unloader: Automates production line flow, reducing manual intervention.

Docking Station: Connects different equipment to mitigate cycle time differences.

Stencils and Jigs: High-quality laser stencils, electropolishing equipment, and qualified PCB support jigs.

Material Storage: Establishes storage and management standards for moisture-sensitive and electrostatically sensitive components (MSD, ESD).

Solder Paste Management: Refrigeration, rewarming, and mixing standards.

IV. Personnel, Software, and Management

Team Building:

Technical Staff: Recruit or develop equipment operators, programmers, process engineers, and maintenance engineers.

Training: On-site training from the equipment supplier is crucial. The team must master programming, optimization, routine maintenance, and troubleshooting skills.

Software and Data Management:

MES: It is strongly recommended to implement a Manufacturing Execution System (MES) for material traceability, production status monitoring, quality management, and process management. It is the foundation for achieving a digital factory.

Programming and Optimization Software: Evaluate the usability of the equipment's built-in software and whether third-party optimization software (such as Valor and CAM350) can improve programming and placement efficiency.

Processes and Documentation:

Establish SOPs: Develop standard operating procedures for all operations (startup, shutdown, line changeover, and equipment maintenance).

Quality Control Plan: Define the inspection standards and sampling frequency for each process.

Preventive Maintenance Plan: Develop detailed daily, weekly, monthly, and annual maintenance plans and strictly adhere to them.

SMT Production Line

SMT Production Line

Submitted, thank you for your consultation!!